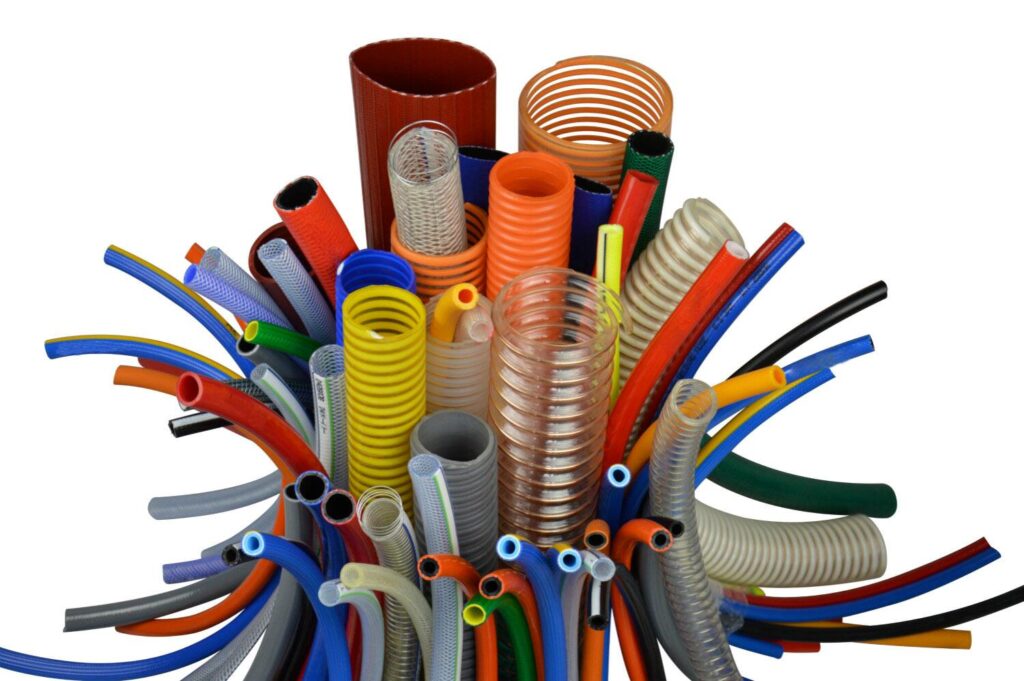

PVC hoses have become essential in countless industries, from agriculture and construction to automotive and food processing. These flexible, durable solutions provide a reliable means of transporting fluids, gases, and materials. But behind every high-quality PVC hose lies a meticulous manufacturing process, one that ensures durability, performance, and reliability. This article delves into the world of PVC hose manufacturing, highlighting the science, precision, and craftsmanship that go into producing these indispensable tools.

The Raw Material: What Makes PVC Ideal?

Polyvinyl chloride (PVC) is a synthetic plastic polymer, widely recognized for its toughness, resistance to abrasion, and flexibility. These qualities make it an ideal material for hose production. PVC hoses are capable of withstanding various environmental stresses, from extreme temperatures to chemical exposure, all while maintaining their flexibility and structural integrity.

One of the key reasons PVC stands out in hose manufacturing is its chemical resistance. Unlike rubber, which may degrade over time due to exposure to chemicals or oils, PVC remains resilient, making it perfect for industries like automotive or chemical processing, where exposure to corrosive materials is common.

The Manufacturing Process: Precision Meets Innovation

Creating a PVC hose starts with the selection of high-quality raw materials. Manufacturers carefully choose PVC resins and additives, such as plasticizers, stabilizers, and colorants, to meet the desired hose specifications. These additives enhance the flexibility, strength, and resistance of the PVC, allowing manufacturers to tailor hoses to specific industrial needs.

The next step is extrusion. During this process, the PVC compound is heated and forced through a die, shaping it into a continuous tube. The extrusion process must be precisely controlled to ensure consistent wall thickness and diameter, which directly impacts the hose’s strength and durability.

For applications requiring extra strength, manufacturers reinforce PVC hoses with layers of woven fiber or steel wire. This reinforcement is often crucial for high-pressure hoses, such as those used in hydraulic systems, ensuring they maintain their shape under extreme conditions. After reinforcement, the hoses go through a cooling and curing process, which solidifies the structure, giving them the flexibility and durability needed for various applications.

Quality Control: The Key to Reliability

One of the most critical aspects of PVC hose manufacturing is quality control. Leading manufacturers implement stringent testing protocols to ensure that each hose meets industry standards. This involves testing for factors like pressure resistance, flexibility, chemical compatibility, and durability under extreme temperatures.

Visual inspection is also an essential part of quality control. Manufacturers check for any defects, such as air bubbles, cracks, or inconsistencies in thickness, which could compromise the hose’s performance. Only hoses that meet all of these quality criteria move on to packaging and distribution, ensuring customers receive a product they can rely on.

The Role of Customization in Manufacturing

No two industries are exactly the same, and neither are their needs. This is why many PVC HOSE Manufacturer offer customization options. Whether it’s a specific size, color, or material reinforcement, manufacturers can tailor PVC hoses to meet the unique requirements of different industries.

For instance, food-grade PVC hoses must meet stringent hygiene standards and be free from toxic chemicals, while construction hoses must be abrasion-resistant to handle the rough demands of transporting heavy materials like sand or cement. The ability to customize hoses allows manufacturers to serve a wide range of industries, each with its own set of challenges and demands.

Why PVC Hoses Are the Industry Standard

In the world of fluid and material transfer, reliability is non-negotiable. Industries cannot afford downtime due to hose failure. PVC hoses offer a winning combination of flexibility, durability, and resistance to a wide range of environmental factors, making them the industry standard across the board.

Manufacturers who prioritize precision, quality, and innovation in the production process ensure that every coil of PVC hose is built to last. From the selection of raw materials to the final quality checks, PVC hose manufacturing is a sophisticated process that guarantees performance, longevity, and peace of mind.

Conclusion: The Craftsmanship Behind the Coil

PVC HOSE Manufacturer may appear simple on the surface, but their manufacturing process involves a high degree of craftsmanship and engineering. Manufacturers continue to innovate, developing hoses that meet the evolving needs of industries across the globe. As the demand for more durable, customizable, and efficient solutions grows, PVC hose manufacturing will continue to be at the forefront of industrial innovation, crafting reliability in every coil.