Understanding the Fundamentals of LED Curable Ink

LED curable ink is at the forefront of modern printing technology, uniquely formulated to cure quickly upon exposure to LED light. This innovative approach not only enhances productivity but also ensures that prints are robust and of high quality. As industries look for efficient methods to produce durable prints, understanding the properties and applications of led curable ink is crucial. It can be used across various printing materials, such as paper, plastics, and metals, making it an ideal choice for both small and large businesses looking to expand their printing capabilities.

Applications That Showcase the Versatility of LED Curable Ink

One of the defining aspects of LED curable ink is its versatility in various applications. Industries such as packaging, labels, and textiles witness the significant benefits of adopting this technology. For instance, a packaging company that shifted to led curable ink reported reducing drying times from hours to mere minutes, allowing them to meet tighter deadlines and significantly increase throughput. Furthermore, its low volatile organic compound (VOC) content ensures compliance with environmental regulations, making it a responsible choice for eco-conscious manufacturers.

Enhancing Print Quality with LED UV Offset Inks

As a cutting-edge solution, led uv offset inks have transformed the conventional offset printing process. By leveraging the curing properties of LED technology, these inks achieve vibrant colors and sharp details that are both visually appealing and long-lasting. Users have expressed that transitioning to LED UV offset inks has not only improved the quality of their print products but has also enabled them to reduce waste and operational costs. This is particularly beneficial for companies that strive for sustainability while delivering high-quality prints efficiently.

Exploring the Benefits of UV LED Curable Ink in Printing

The innovation of UV LED curable ink presents numerous benefits for businesses engaged in the printing industry. Its ability to set instantly upon exposure to UV light allows printers to reduce waiting times significantly and streamline their production processes. uv led curable ink is particularly advantageous for achieving high-quality finishes on challenging substrates, including those that are metallic or plastic. Additionally, users have noted exceptional adhesion and durability of prints, which translates to increased customer satisfaction and repeat business.

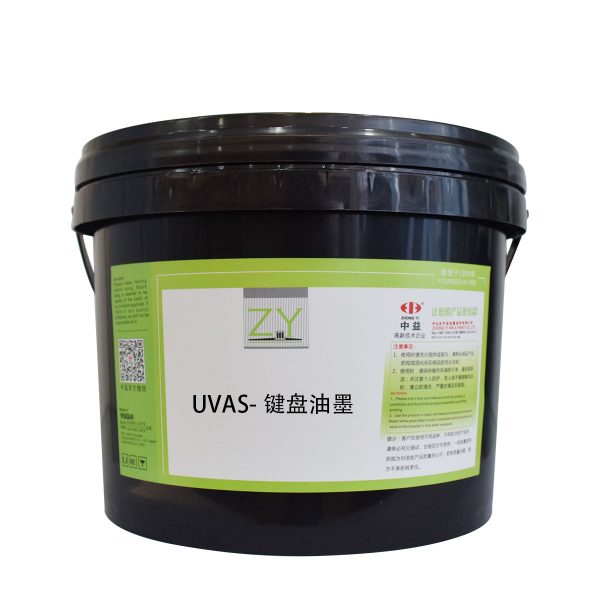

Conclusion: Embracing the Future of Printing with Zhongyiink

In conclusion, the advancements in LED curable ink technology represent a revolutionary shift in the printing landscape. By providing enhanced quality, efficiency, and sustainability, products from reputable manufacturers like Zhongyiink emerge as the preferred choice for businesses aiming to stay competitive in the evolving market. With their commitment to innovation and quality, Zhongyiink stands ready to unleash the full potential of LED curable inks for your printing needs.