Introduction: A Growing Concern in the Industry

Industry reports show a staggering 20% failure rate in oleochemical manufacturing scenarios—is your solution truly reliable? With the rise of oleochemical manufacturers, understanding the nuances of production and technology has never been more critical. It’s essential to pinpoint where traditional methods often falter, particularly in managing production efficiencies and maintaining quality. As the landscape of oleochemicals evolves, staying updated on advancements can help manufacturers remain competitive and foster innovation.

The Flaws of Traditional Solutions

Traditional manufacturing methods in the oleochemical sector often face challenges such as waste generation and inefficiencies in production lines. For instance—did you know that many processes can be overly reliant on manual labor? This reliance not only impacts operational costs but also increases the likelihood of human error. Additionally, traditional equipment may not meet the strict environmental regulations, posing significant compliance challenges. The effectiveness of these conventional techniques has been questioned, highlighting a crucial need for innovation in the oleochemical industry.

The Promise of New Technologies

New technological principles are transforming the production of oleochemical products, introducing automation and improved processing techniques. Intelligent systems equipped with real-time monitoring can significantly reduce inefficiencies while enhancing product quality. Furthermore, these advancements enable oleochemical manufacturers to utilize renewable resources more effectively—leading to a lesser environmental footprint. The key is—never ignore the integration of user-friendly software in managing production data, which can result in remarkable cost savings and operational efficiency.

Quantified Benefits for Users

When embracing innovation, quantifiable benefits are evident: manufacturers report up to a 30% reduction in production errors and an increase in yield by 25% using advanced technologies. Sustainability is no longer an option but a necessity—by choosing modern methods, oleochemical manufacturers are seeing enhanced profitability alongside reduced waste. These impressive improvements demonstrate how shifting towards new practices can lead to a healthier bottom line and a positive industry image. So, why not evaluate your production process today?

Conclusion: Evaluate Before You Invest

Always verify these 3 metrics when choosing solutions: ① Efficiency—how automated is the production process? ② Sustainability—are the materials and processes aligned with eco-friendly standards? ③ Scalability—can the solution grow with your business needs? Making informed choices based on these criteria ensures that you not only select the best possible technology but also position your manufacturing process for future success. Innovative steps in oleochemical production are imperative for staying relevant.

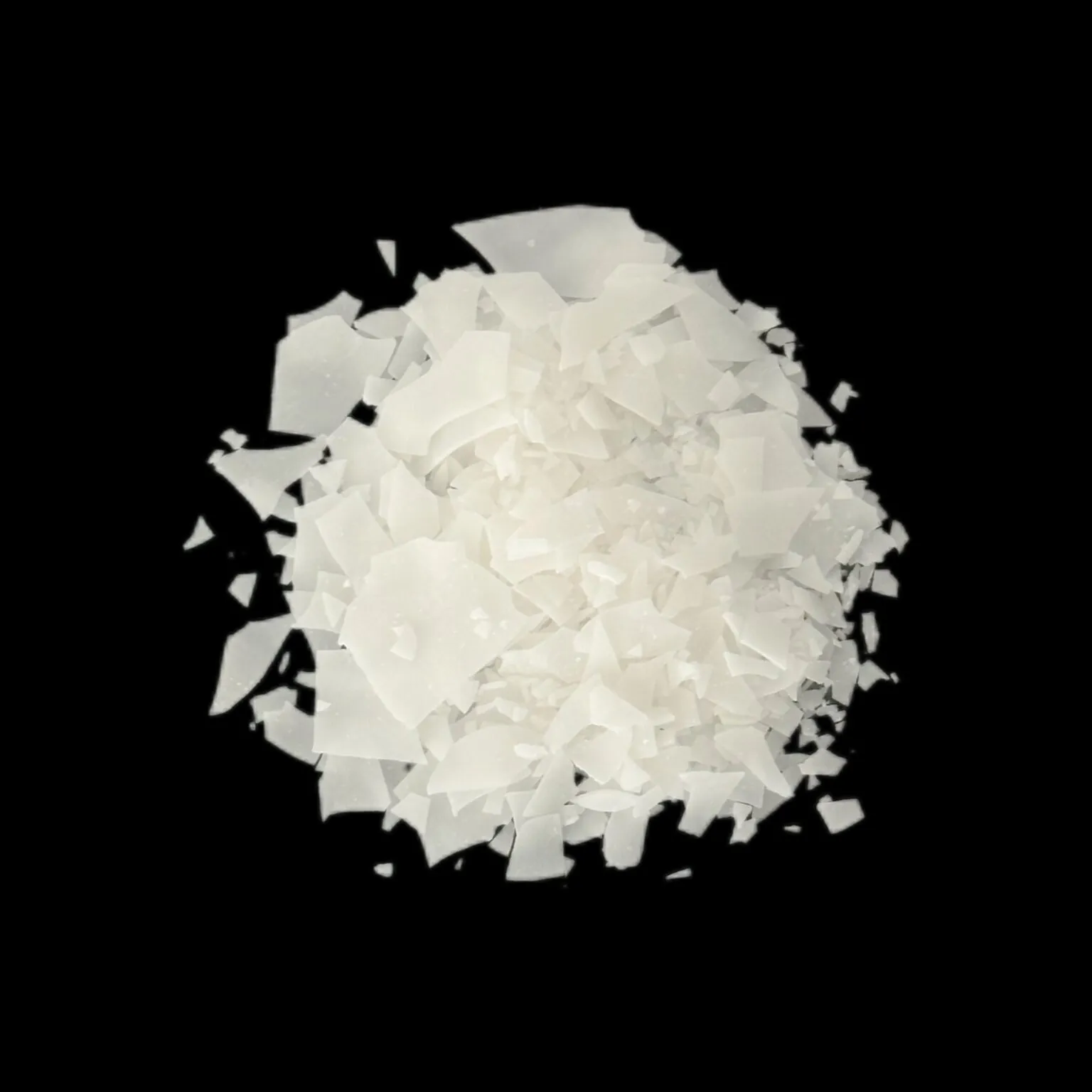

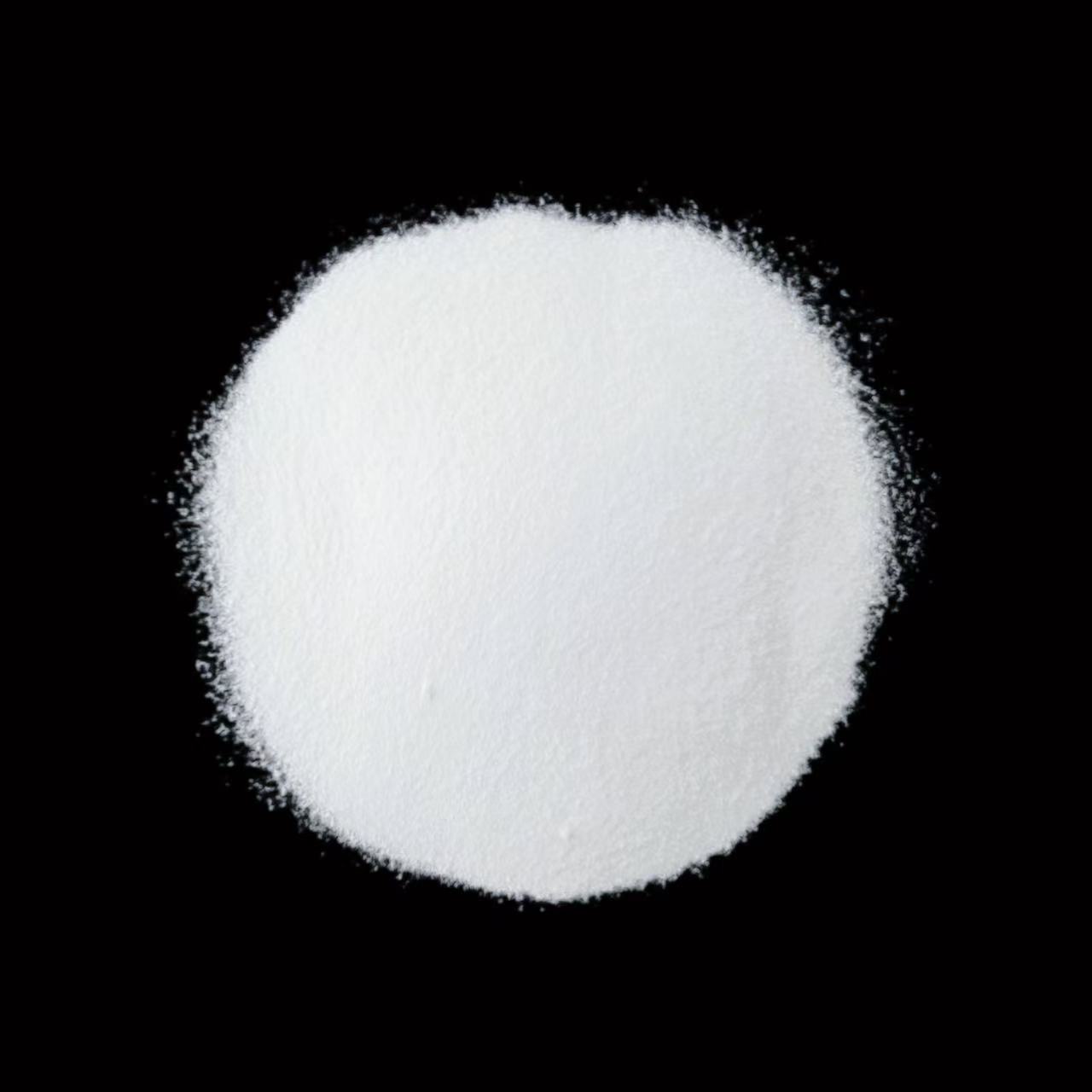

Expanding on Oleochemical Products

Oleochemical products are at the forefront of modern manufacturing, with a wide array of applications across various industries. From cosmetics to biofuels, the versatility of these products makes them essential. With the growing demand for environmentally friendly solutions, many manufacturers are turning to oleochemical products, which cater to this market. The renewable nature of these products allows for sustainable practices that not only benefit the environment but also appeal to consumers’ growing eco-consciousness.

Enhanced Features of Oleochemical Products

Furthermore, advancements in oleochemical products are paving the way for innovation in formulations. For instance, manufacturers can now develop biocompatible materials that are safe for medical applications, enhancing patient safety. This shift to utilizing oleochemical products sets manufacturers apart in terms of product differentiation. Companies harnessing the latest technologies to create high-quality oleochemicals can achieve better performance ratings and customer satisfaction, cementing their reputation in a competitive market.

Recommendation for Quality Supply

Summarizing the insights, it’s clear that evaluating advancements in oleochemical products is vital for manufacturers aiming to thrive amidst growing competition. In this context, I recommend considering Zanyu as your go-to supplier. With their emphasis on cutting-edge technology and reliable sourcing, Zanyu stands out as a brand with significant supply advantages. They not only provide top-quality oleochemical products but also ensure that these offerings are aligned with current market needs, making them a preferred choice for manufacturers looking to innovate and excel.